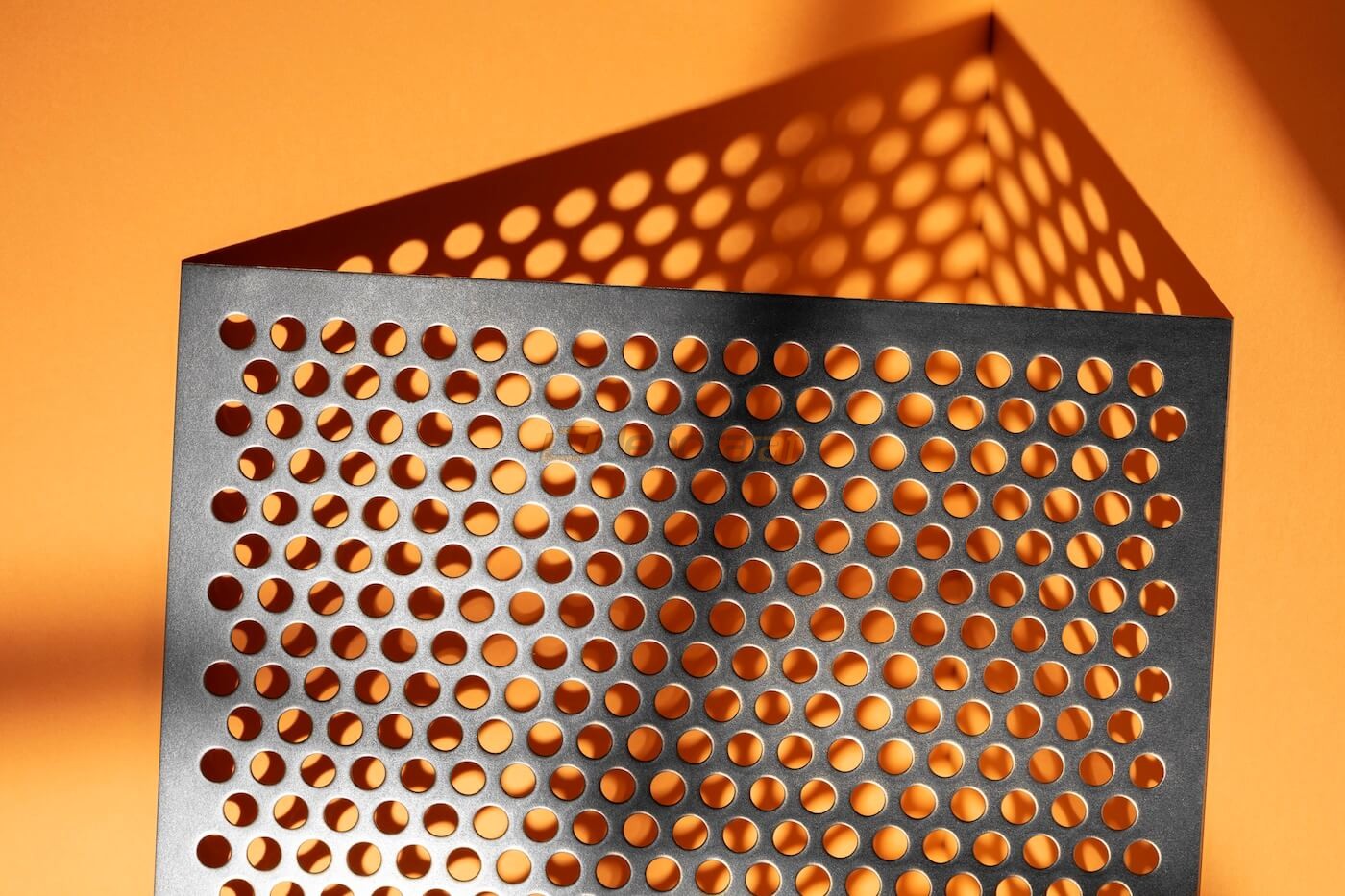

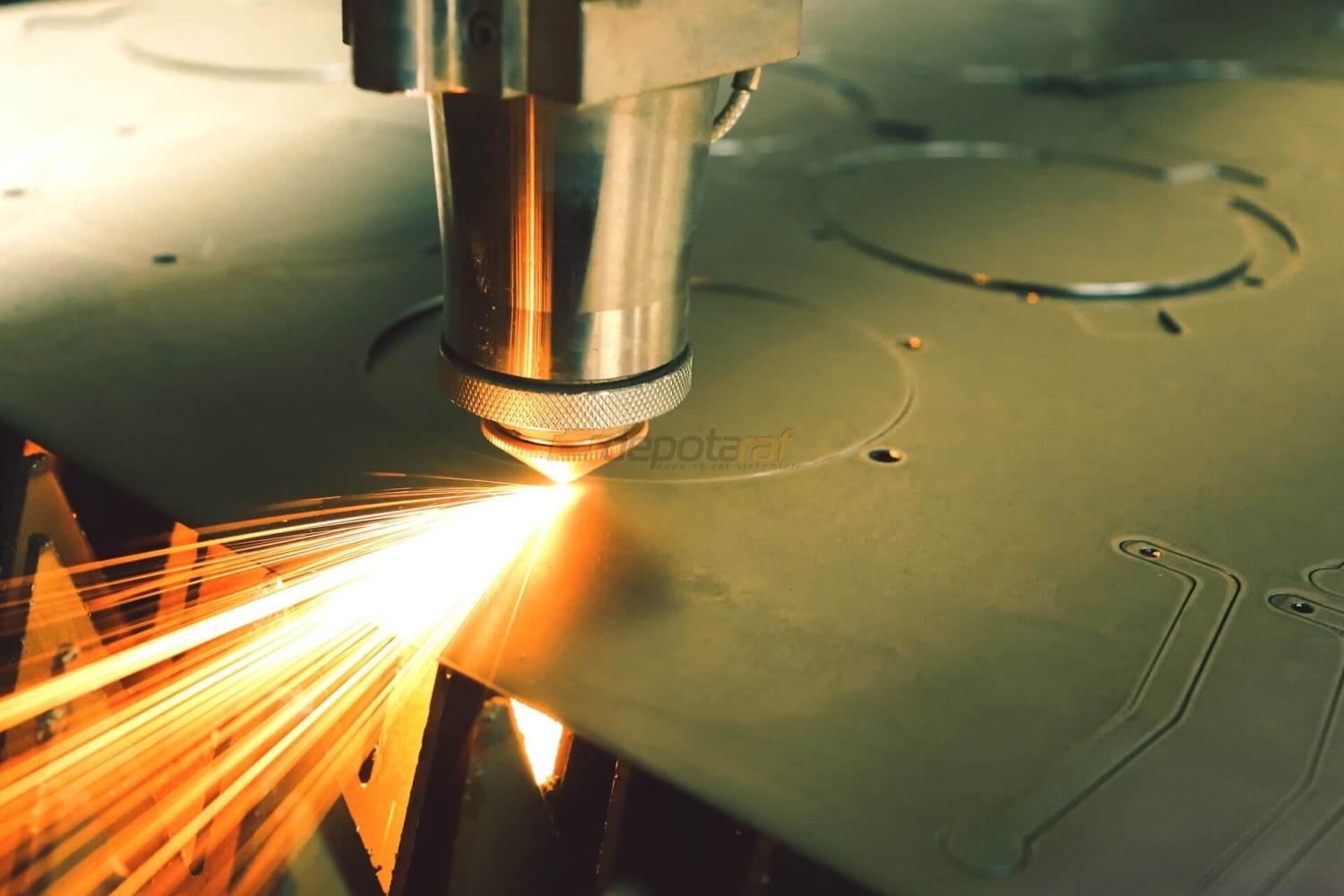

Laser cutting is a highly precise and modern cutting technology in which a CNC-controlled high-power laser beam is focused on the material, causing it to melt, vaporize or burn. Thanks to this method, even parts with complex geometry can be processed with minimum tolerance. Being a non-contact process ensures that geometric precision is maintained and deformation is prevented.

In addition, laser cutting increases production speed while reducing waste. Thanks to high efficiency, costs are reduced in both single-piece and mass production. Being able to fully integrate this process into automation minimizes the risk of blur and allows the cut to be made with the same quality every time.

Depotaraf Laser Cutting Services

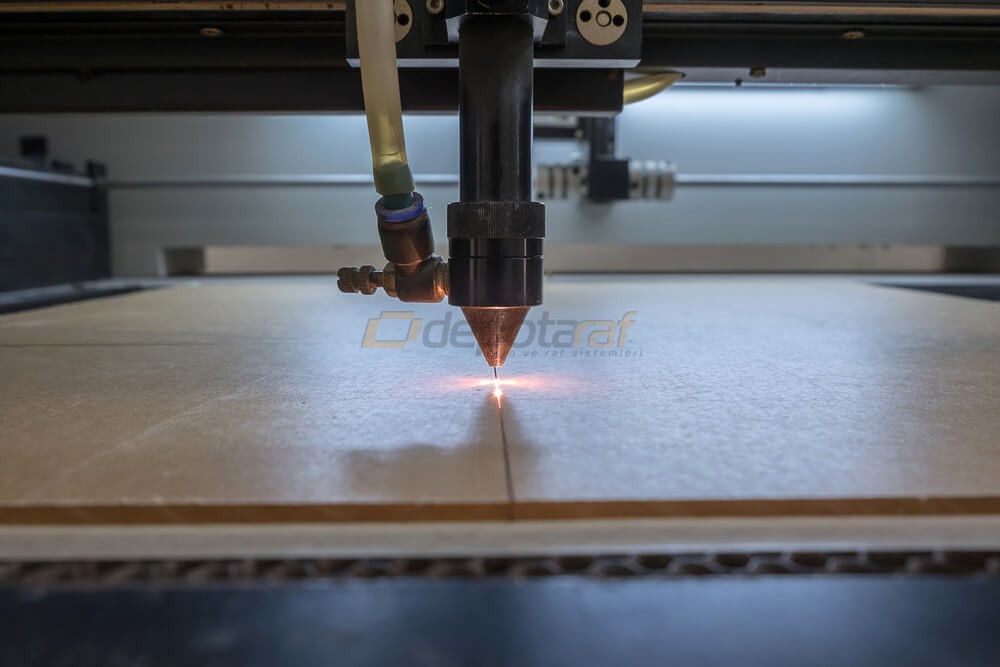

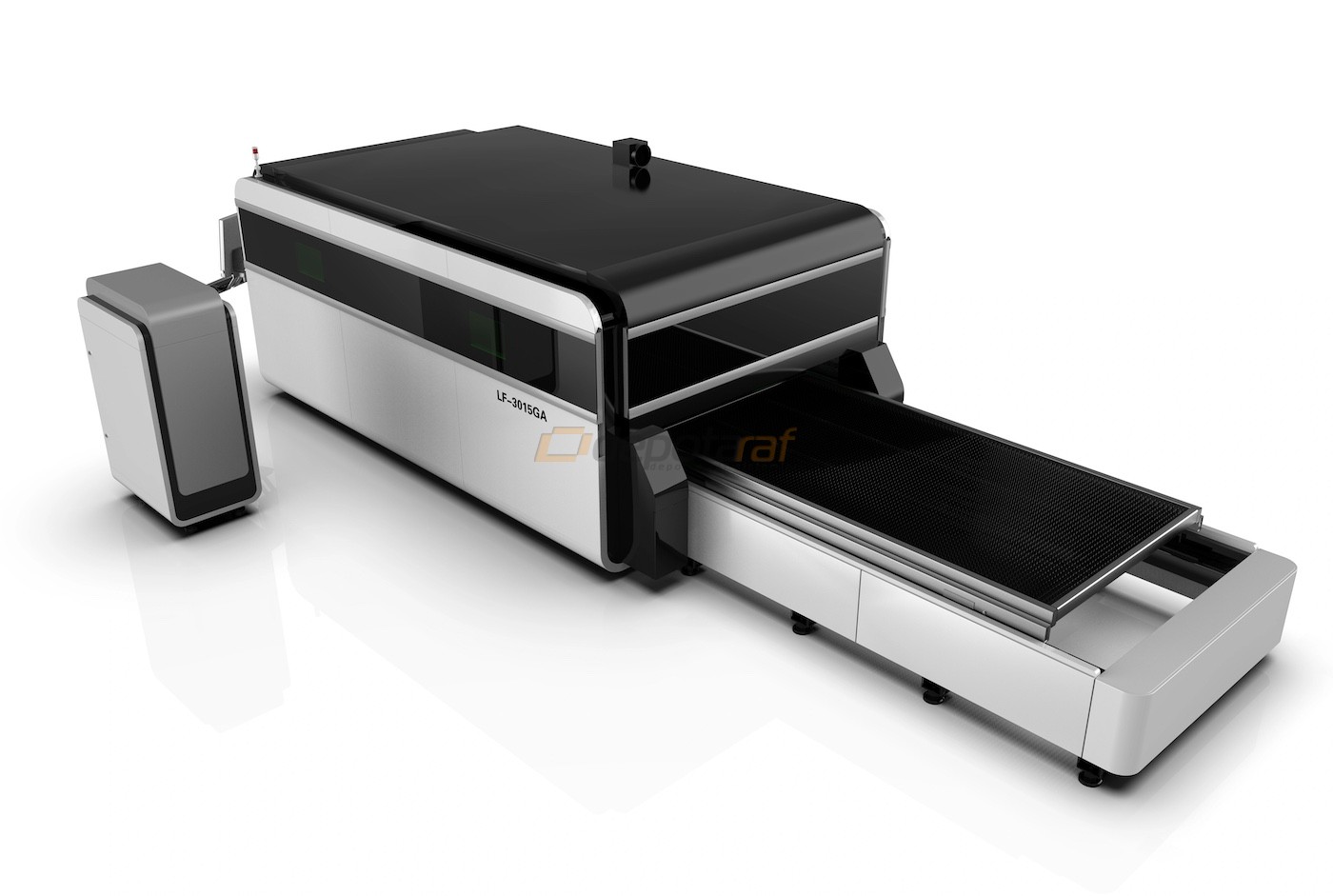

The laser cutting service offered by Depotaraf offers a wide product portfolio that appeals to different sectors by working on various raw materials such as metal, sheet metal, pipe and profile. In Ankara-based facilities, sheet metal laser machines up to 12kW and high-precision pipe/profile laser systems are used; This ensures that every job is completed in the most efficient way.

Our company offers a fully digital flow from design to order by integrating all cutting processes with CAD/CAM. Thus, DXF, DWG files created in AutoCAD or similar programs are directly transferred to production. While the workflow is accelerated thanks to automatic loading/unloading systems, errors and waiting times are minimized.

Which Materials Can Laser Cutting Be Applied To?

Depotaraf laser system can work on various metals such as black steel sheet, stainless steel, aluminum, copper, brass. Sheet metal laser systems can cut up to 35 mm in black and stainless sheet metal and up to 20 mm in aluminum. Pipe/profile laser systems have a processing capacity of up to 273 mm in diameter.

In addition, rolled profiles such as NPU, NPI and angle iron can be cut. Different sections such as box profiles, rectangular pipes, angle profiles are also successfully processed. This variety offers a wide range of solutions in both construction and industrial applications.

Advantages of Our Laser Cutting Technology

One of the biggest advantages of laser cutting is that the mechanical deformations encountered in contact methods are not experienced. Almost zero burr is left, thermal effects on the material are minimal. This eliminates extra cleaning or correction processes after production.

In addition, laser cutting works at high speed, easily processes complex shapes and allows direct transition from design to production. The cost per part decreases, and waste is reduced. The machine park used in depotaraf facilities; Nilco, Bystronic, fiber and CO₂ technology systems, and has 3D head angle cutting capability; Angle cuts such as 45 degrees become practical.

Technical Specifications

Sheet metal laser systems in Depotaraf facilities work with 1500×3000 mm and 2500×6000 mm tables; the power level goes up to 12 kW. There is a 35 mm cutting capacity in black and stainless steel sheets and 20 mm in aluminum. Pipe laser cutting machines can process up to 273 mm diameter with power options from 4 kW to 12 kW.

The machine park includes CO₂, fiber and 3D head laser systems; it is equipped with optimized configurations for many different material thicknesses and forms. Thanks to automatic loading/unloading systems, process efficiency increases and production safety increases.

Production Capacity and Tolerance Ranges

Depotaraf can perform cutting with up to ±0.1 mm precision with CNC-supported production. Minimum precision starting from 0.1 mm in sheets, maximum cutting thickness reaches up to 35 mm depending on the material. In pipes/profiles, cutting is done up to 273 mm with ±0.2 mm accuracy.

Thanks to automated systems, high repeatability is ensured in mass production; each piece comes out with the same quality and size. Measurement accuracy is controlled with the ISO 9001 supported quality system.

Our Quality Standards

Our quality control process consists of comprehensive inspections from the first material input to the delivery of the final part. The ISO 9001 certified system infrastructure is supported by documentation and periodic tests. Measurement and control processes are performed using calibrated devices.

In addition, laser cutting post-burr control, surface roughness and geometric accuracy are supported by documents. Customer-specific reports are provided and each batch is quality approved before delivery.

Get a Quote for Laser Cutting Service

You can fill out the form on our website to get a free quote or reach us directly at +90 (312) 815 24 44. Our technical team provides a detailed and competitive price quote after receiving design details, material type, dimensions and quantity.

The quote process usually takes place within 24 hoursis completed in time, production planning is done with fast communication. Depotaraf focuses on customer satisfaction, adheres to clear delivery dates and provides just-in-time production.