Punch press is a hydraulic or mechanical system work machine that performs punching, shaping and cutting operations on sheet materials quickly and repeatedly. The press pin (punch) operating under high pressure interacts with the mold and creates the desired form on the sheet. With CNC control, even parts with complex geometry are suitable for mass production.

Thanks to this system, production time is shortened, material waste is prevented and repeatability is ensured. Safety, speed and precision are at the forefront in its behavior to a great extent; these are the main reasons why it is preferred especially in the automotive, white goods and electronics sectors.

How Does the Punch Pressing Process Take Place?

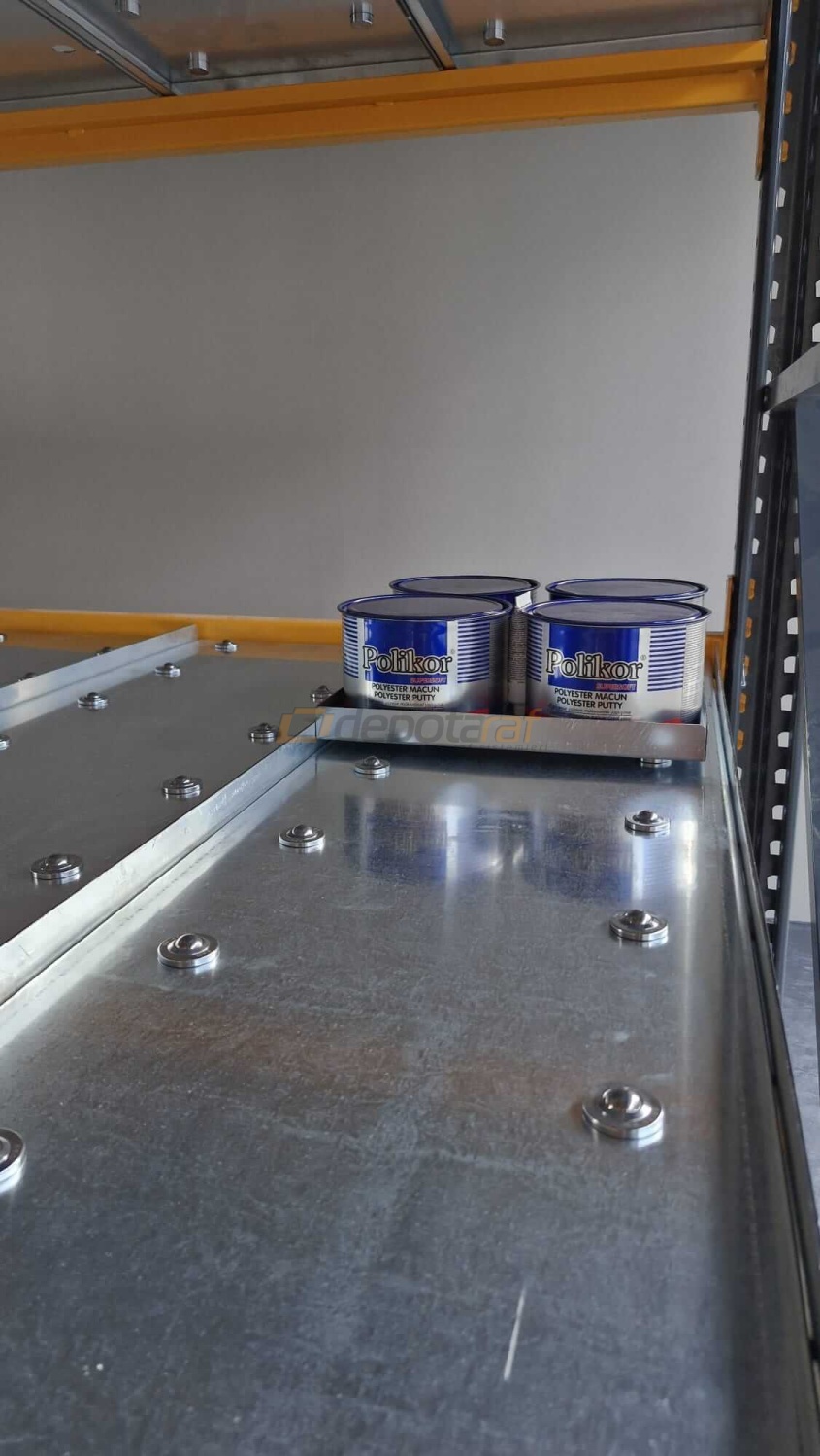

Punch pressing is completed by the punch and matrix molds on the press applying a certain force to the sheet metal and shaping it. When the sheet metal comes into contact with the pin, processes such as punching, shaping or protrusion occur. This step requires the pressure force to be adjusted in accordance with the mold design and sheet metal thickness.

In order to reach the required press speed and maintain part precision, machine power, mold quality and sheet material properties play a critical role. With the right settings, it is possible to produce hundreds of parts in repeatable quality without deformation and excessive waste.

What is Punch Grinding and Why is it Needed?

Punch grinding is the process of re-sharpening the cutting surfaces of punch press molds. The matrix and punches wear out over time, the cutting gap increases, burrs and poor quality occur. With the grinding process, the cutting edges become sharp, the cutting surface is cleaned and the part quality reaches its optimum again.

This process is both a necessary maintenance process for worn molds and a step that increases production efficiency. Punch grinding performed at correct intervals extends mold life and reduces total production costs. It also positively affects product repeatability.

Punch Press Mold Grinding Process

Punch press mold grinding is performed on professional grinding machines; It is performed with automatic or manual systems suitable for molds with a diameter range of 3mm–180mm. In this process, surface quality is maintained by using grinding stones with cooling systems.

In PLC-controlled systems, grinding parameters are entered via the touch screen, the amount of wear is determined and the grinding process is applied in the most precise way. As a result, both the punch and the matrix are sharpened at the same time, the cutting gap is pulled to the ideal range and production quality is guaranteed.

What are the Advantages of Punch Press Molds?

The biggest advantages of using punch presses are; high speed, repeatability, suitability for automation and low operating costs. In addition, when molds are constantly maintained with punch grinding, the waste rate and quality production continuity are ensured.

With this system, mold life is extended, preparation time is shortened, and there is no deviation in quality standards during production. This is the way to produce sharp, clear holes and shapes in the automotive and white goods production line.

In Which Sectors Is Punch Press Used?

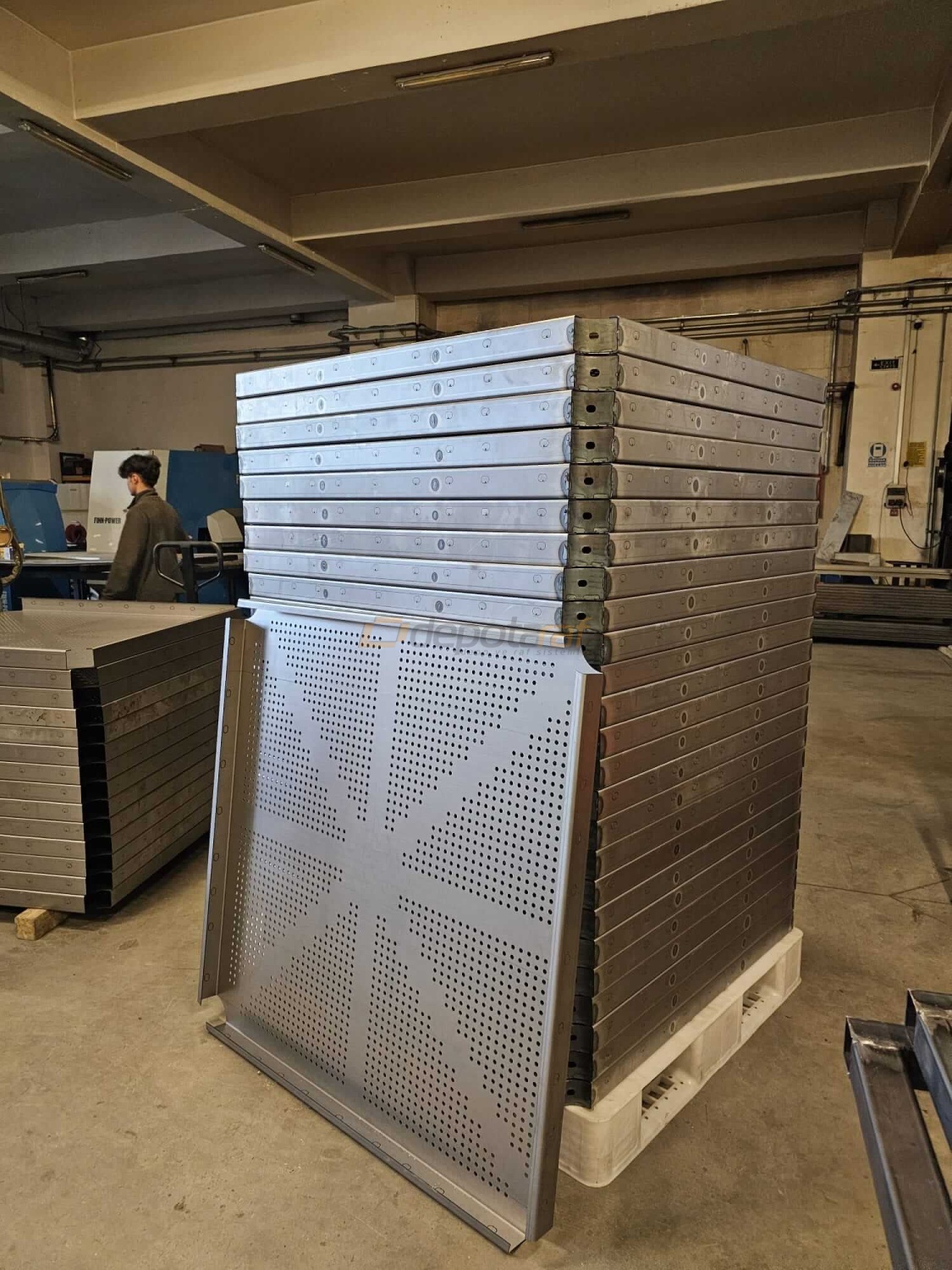

From automotive components to electronic device cases; from home appliances to construction fittings, many industries produce with punch presses. At the same time, metal furniture and ventilation ducts are also produced with high quality with this system.

Thanks to this flexibility, the desired form, hole and shape can be obtained in both prototype and mass production parts in a single pass and with high precision.

How Does the Offer Process Proceed?

To receive an offer, part drawings (such as DXF, DWG), material type, thickness and number of pieces are shared. The technical team determines the appropriate mold and grinding range. After the detail approval, production is planned and the delivery process is started.

For those who want customized grinding or punching, we offer quick turnaround, clear and competitive pricing.