In a period when competition in industrial production is increasing, speed, precision and quality in the production line are no longer just a choice, they have become a necessity. Sheet metal forming processes constitute the cornerstones of production in many sectors, especially from automotive to white goods. At this point, Punch Press and Die Grinding technologies are creating a revolution in production processes. Perfect cutting precision, speed that comes with automation and the ability to produce without compromising on quality place these systems at the center of industrial transformation.

Punch press machines and die grinding services offer serious advantages for companies that want to optimize sheet metal forming operations. Moreover, they increase their competitive power by directly affecting not only production quality but also production time and costs. Innovative companies such as Pass Dijital offer these technologies and take industrial efficiency to the next level. The basis of this transformation is the smartness of the machine and the long-lasting and precise protection of the molds.

The Power of Punch Press Technology and Application Areas

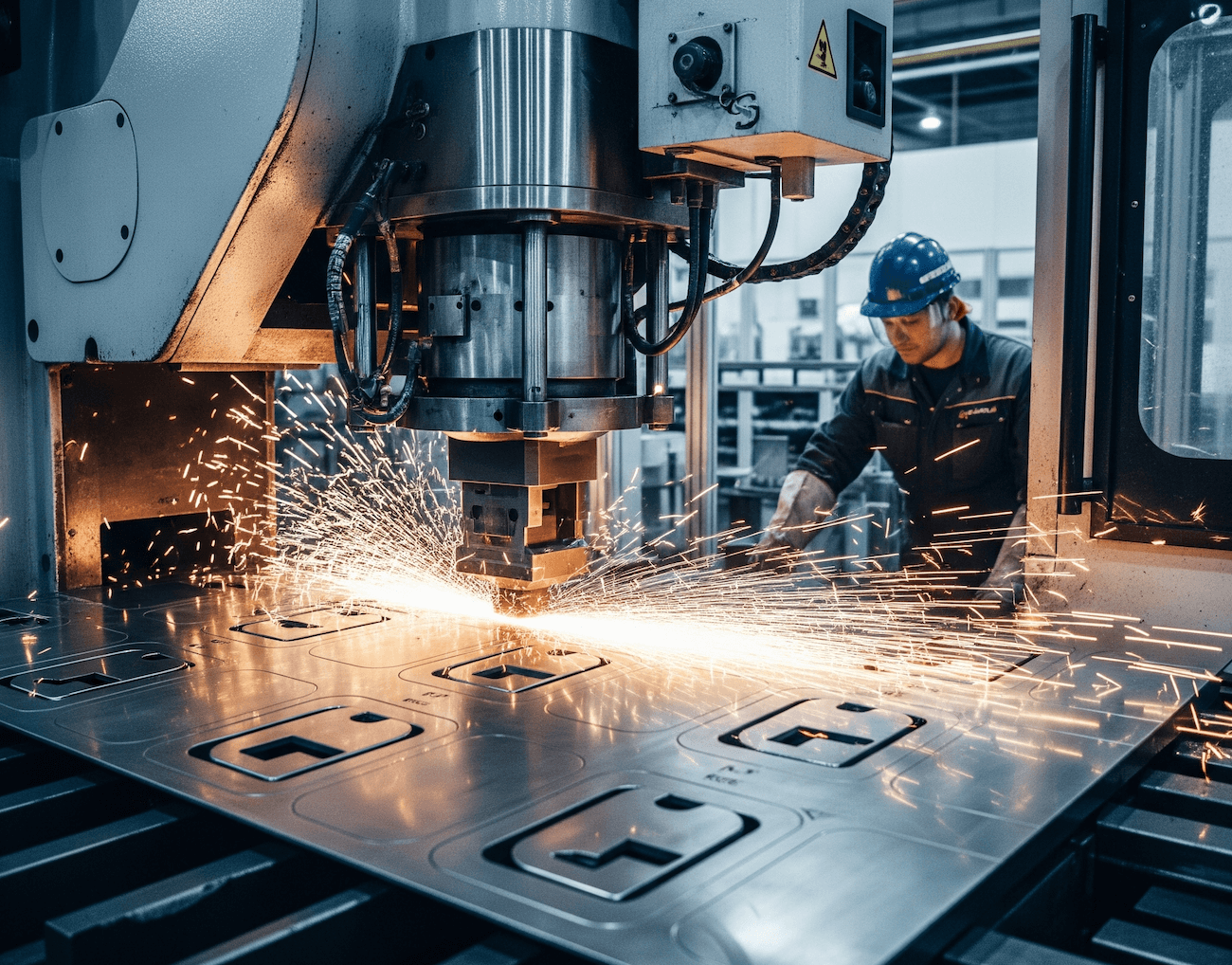

Punch press machines; These are advanced systems that provide high speed and repeatability in the punching, cutting and shaping processes of metal sheets. This technology, which is used in many different areas of industrial production, offers ideal solutions especially for mass production. It is widely used in areas such as automotive, defense industry, white goods, furniture and electrical panels; It enables production to become more efficient, precise and economical. High-pressure processes make it possible to reach maximum production capacity with minimum margin of error.

What is Punch Press? The Secret of Fast and Precise Production

Punch press is a production technique applied to give metal sheets a certain form. In this system, various shapes are given to the sheet material with the help of molds and punches. Punch press machines, which usually work with CNC-supported systems, perform fast and repeatable cuts with automatic programming. In this way, human error in production is minimized and the quality standard is maximized.

These machines can quickly perform processes such as punching, cutting and shaping sheet metals of various thicknesses. Punch presses provide the opportunity to obtain more products at lower costs compared to classical methods. In addition, thanks to the molds used, each product is produced to the same standard. This is a factor that directly affects customer satisfaction. Precise processing of sheet metal contributes to the smooth progress of subsequent welding or assembly processes.

Along with the digital transformation in the industry, punch press systems have also become more functional by being supported by advanced software. Thanks to features such as automatic tool change, programmable punching patterns and remote monitoring, manufacturers save time and labor. This not only speeds up production, but also optimizes quality control processes.

The Difference of CNC Punch Presses in Automation and Efficiency

CNC punch press machines offer much higher efficiency than traditional press systems. Thanks to CNC technology, the machines operate via computer-controlled software, which provides great flexibility to the user. The operator only makes the necessary coding via the digital interface, and then the machine performs the desired process with millimeter precision.

Such automation systems reduce operator errors to almost zero. In addition, automatic switching of different geometries and molds prevents loss of time during production. This is a great advantage for companies that produce in high volumes. CNC punch press systems save time while also significantly reducing labor costs.

In addition, since these machines have a modular structure, they can be easily reprogrammed according to new production needs. This gives businesses great flexibility in expanding their product range. Increasing efficiency and optimizing energy use also reveal the importance of these systems in terms of sustainability. Companies such as Pass Dijital offer comprehensive solutions to industrial manufacturers at this point, providing both quality and cost advantages.

Advantages of Using Punch Presses in Industry

The area of use of punch press technology in industry is quite wide. This system offers an indispensable solution for low tolerance and high precision production demands. Product variety and quality are directly related to the flexible programming and high processing speed offered by punch press technology. In addition, minimizing material waste supports environmentally friendly production processes.

Another important advantage is that it can be adapted to many different product types. Many different molds can be used on the same machine and these molds can be easily changed during production processes. This reduces investment costs in a short time.allows time to recover. Savings in time and labor in high-volume production offer manufacturers a great competitive advantage.

The high precision offered by punch press machines directly affects product quality while also reducing the error rate. This reduces the burden on quality control processes. In addition, its low maintenance requirement and long-lasting structure increase the cost advantage for businesses. In addition to advanced machines, mold grinding solutions that work integrated with these systems also reinforce the efficiency of the process.

Mold Grinding: The Key to Quality and Continuity in Production

Mold grinding is one of the most critical steps in maintaining quality and continuity in metal shaping processes. Especially in productions that require high precision, the smoothness and regularity of the molds directly affects product quality. The molds used in punch press machines can wear out, deteriorate or deform at the micron level over time. This causes both unwanted marks on the product and production losses. The mold grinding process is an effective maintenance and repair method used to prevent such problems.

By reshaping the mold surface, burr formation (serrated edges) is especially prevented and a smooth cut is provided on the material. In addition, the life of the molds is extended thanks to the grinding process, which enables uninterrupted operation in the production line. In terms of continuity of production, mold grinding is not only maintenance but also a quality assurance strategy. This process is included in the planned maintenance systems in production facilities, preventing unexpected stops and failures.

Why is Mold Grinding Important? Assurance of Burr-Free Production

Small burrs called burrs in metalworking processes are usually caused by mold wear or insufficient cutting quality. These burrs create unwanted protrusions on the product surface, negatively affecting both the visual quality and the functionality of the product. Especially in sensitive applications such as the automotive or defense industries, burr-free production has become a necessity. This is where the mold grinding process comes into play.

Mold grinding eliminates deformations on the surface of the molds and creates flat, smooth and sharp lines. This provides excellent cutting quality in sheet metal forming processes. In addition, preventing burr formation increases end-user satisfaction and saves time in subsequent welding, painting or assembly processes. Each part is important in the processes that the product goes through until it reaches its final state, and mold grinding is one of the most critical steps in this process.

Another important point is quality standardization. Being able to produce the same quality product in each production batch depends on the homogeneity of the mold surfaces. Therefore, grinding at regular intervals minimizes quality differences in production and provides a stable production process. This is a parameter that directly affects customer satisfaction. Companies such as Pass Dijital provide manufacturers with the opportunity to manage this process professionally with the technical solutions they offer in this field.

Reduce Production Costs with Precise Mold Maintenance

The mold grinding process directly affects not only quality but also cost management. Frequent stoppages in the production process are often caused by reasons such as mold deterioration or wear. This situation not only leads to loss of time, but also to increased product waste, disruption of production planning and indirect delays in customer delivery times. However, regular precision mold grinding is one of the most effective ways to prevent all these problems and reduce production costs.

A certain number of operations are expected to be performed throughout the life of a mold. However, this life can be extended or shortened depending on the conditions of use and the quality of maintenance. Grinding the mold surface at certain intervals ensures less stress on the material and therefore extends the life of the mold. Thus, the frequency of new mold investments decreases, which means serious savings in the long term.

In addition, ensuring continuity in production is also of great importance in terms of efficient operation of the machines. When the mold breaks down, not only that part but the entire production line can stop. This means unnecessary expenditure in many items from labor costs to energy. With precision grinding, such disruptions are minimized and production continues as planned. For companies looking to increase quality while reducing costs, mold grinding is no longer a luxury, it is a necessity.

Mold Grinding Strategies for Extending Tool Life

Tools and molds are one of the most expensive components of manufacturing processes. Therefore, extending tool life is at the core of manufacturing strategies. Mold grinding not only repairs existing damage; it alsoIt also increases the surface quality of the molds and ensures that they perform longer. This reduces both tool costs and offers a great advantage in terms of production continuity.

One of the strategies that can be applied to extend tool life is grinding operations performed at certain periods. In this way, microscopic cracks, surface deterioration or metal fatigue that occur in the molds can be prevented. In addition, cleaning the particles that will damage the mold during the grinding process provides a healthier cutting process. This prevents deformations that may occur on the product.

In addition, the grinding process is quite critical for keeping the tolerance values of the molds constant. Mold openings that expand or narrow over time can cause deviations in production. These deviations are eliminated with the grinding process and the mold is preserved as close to its factory-exit values. In this way, every production part comes out with the same quality. This reduces the error rate in high-volume production and reduces quality control costs. With the grinding services offered by Pass Dijital, it becomes possible to manage tool life efficiently.

Frequently Asked Questions About Punch Press and Die Grinding

- In which sectors are punch press machines used?

Punch press machines are widely used in the automotive, defense industry, white goods, electrical-electronics and furniture sectors. They are preferred in these areas because they offer high precision in punching, cutting and shaping processes. - What is the main difference between CNC punch press and manual press?

CNC punch press machines are computer controlled and programmable. This means higher production speed, less error rate and more complex cutting processes. This precision and speed are not possible in manual systems. - How often should die grinding be done?

The die grinding process varies depending on the production intensity and the material used. However, it is recommended to grind on average every 10,000 - 20,000 production cycles. - What equipment is used in mold grinding?

Surface grinding machines, precision measuring devices and special cooling systems are used for mold grinding. Surface improvements can be made at the micron level with this equipment. - How much does mold grinding extend tool life?

Regular grinding can extend tool life by an average of 30% - 50% by reducing mold surface wear. This provides a significant cost advantage in the long term.